Use Case: Occupancy-Based Load Control

Reduce energy consumption and maintenance of ancillary equipment with SiteWorx Sense

Today more than ever, energy efficiency is critical to running a successful operation. Installing intelligent lighting and controls is a great first step to reducing energy use and costs, and reach wider corporate sustainability goals. However, there are opportunities for facilities to do much more beyond the installation of intelligent lighting to further increase these energy savings.

Most industrial spaces, like manufacturing, distribution, food and beverage production facilities, have HVAC systems, fans, compressors, conveyor belts, and much more equipment, that can be extremely energy-consuming. Without efficient ways to turn this equipment on and off, many of these systems can be left on 24/7, even if not being used, or if the facility sits empty for hours on end. This not only results in unnecessary energy use but in potential additional maintenance costs from keeping the equipment continuously running.

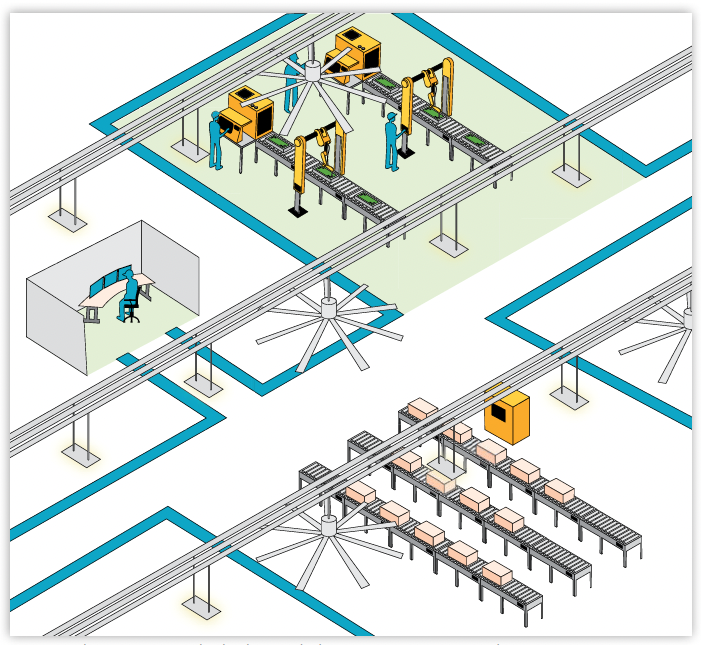

A typical factory floor with lighting, ventilation, conveyor belts, and equipment used by workers. SiteWorx enables energy monitoring not only for lighting — but all types of equipment.

SiteWorx Sense-enabled occupancy-based load control can help minimize unnecessary energy use of this industrial equipment in the same way that integrated occupancy sensors can be used to control lighting in SiteWorx Tune. That same occupancy data used to optimize lighting energy usage can be used to effectively turn equipment on or off by opening and closing relays in two SiteWorx devices — the Wireless Input/Output (SWN-WIO) or the Smart Cord (SWN-CRD).

This allows SiteWorx users to turn on and off any unintelligent plug-load when connected through the SWN-CRD, once user-configured occupancy thresholds are reached.

For more complex, circuit-level control that expands beyond turning loads on or off, the SWN-WIO can be used to open and close its integrated relay for things like PLC integration in response to user-configured occupancy thresholds.

Related Articles

Configure Occupancy Based Load Control (OBLC)

Before configuring load control, read the Load Control Overview. How does load control work? A user creates a Trigger Group - a group of Trigger Nodes (whose occupancy data will be used to trigger a relay) A user assigns activation threshold criteria ...Manual Load Control

Manual load controls enable a user to override a configured Occupancy-Based Load Control (OBLC) setting. Manual load controls are also useful for testing the wiring to ensure the load is controlled as expected and for testing connection to a Building ...Load Control Overview

SiteWorx Sense Load Control allows controls (like occupancy sensors, manual control, or schedule-based controls) turn equipment on or off. Load Control Terminology Load Control: Opening or closing a relay, usually as a means of turning a load “on or ...Use Case: Occupancy Data-Driven Cleaning

Occupancy data helps you manage cleaning efforts with SiteWorx Area As a result of unexpected shut-downs, facilities have had to adapt how they perform every-day operations to ensure the success of their business, and the safety of their employees, ...Use Case: Data Reporting

Identify and report on energy-saving achievements SiteWorx Analyze helps customers examine and understand data and insights from their facilities. The easy-to-use data visualization tools lets customers interact with various types of data gathered ...